3D printers working in the millimeter range and larger are increasingly used in industrial production processes. Many applications, however, require precise printing on the micrometer scale at a far higher speed.

Now, researchers at Karlsruhe Institute of Technology (KIT) have developed a system to print highly precise, centimerter-sized objects with submicrometer details at unmatched speeds. Their work was recently published in Advanced Functional Materials.

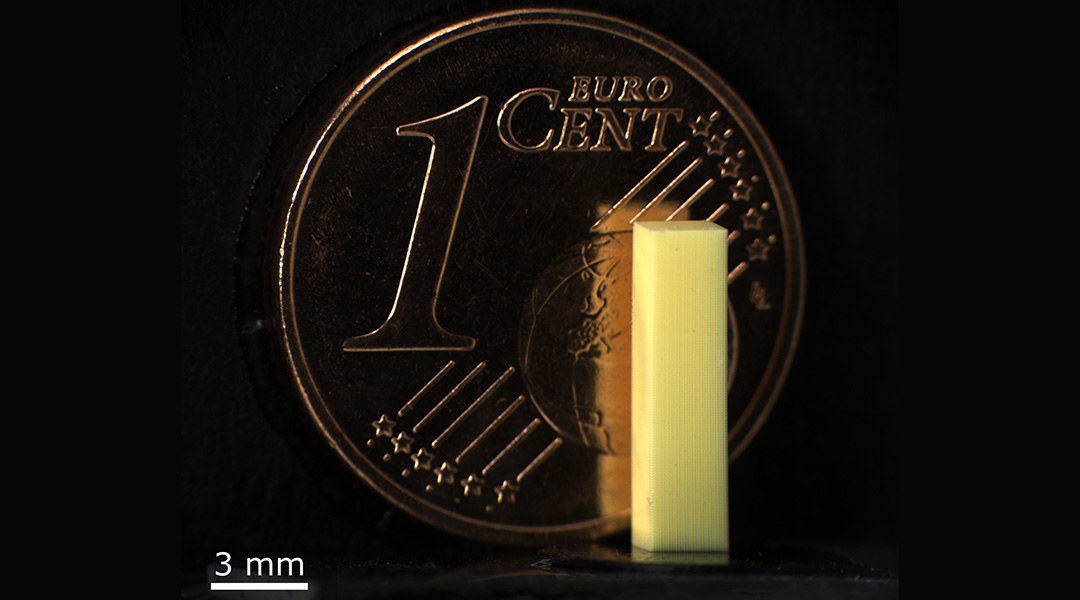

To demonstrate not only the speed, but also the reliability of their setup, the team printed a lattice structure of 60 cubic millimeters in size with details down to the micrometer scale. It contains more than 300 billion voxels. (A voxel is the three-dimensional analogue of the pixel in the 2D printing).

“We have by far outperformed the record reached by 3D-printed aircraft wings. This is a new world record,” says Martin Wegener, professor at KIT and spokesperson for the Cluster of Excellenece. “3D Matter Made to Order (3DMM2O), within the framework of which the system was developed.

For this type of 3D printing, the beam of a laser passes through a photoresist in a computer-controlled manner. Only the material located in the focus of the laser is exposed and cured.

“The focal points correspond to the nozzles in inkjet printers, with the difference that they work in three dimensions,” says Vincent Hahn, first author of the publication.

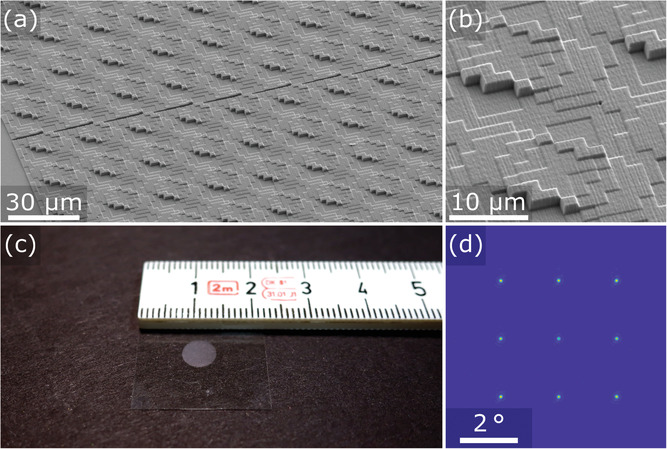

In this way, highly precise filigree structures can be produced for various applications, such as optics and photonics, material sciences, biotechnology, or safety engineering. Typically, several hundred thousand vocels per second have been produced with a single laser light beam. This means that it was nearly a hundred times slower than graphical inkjet printers, which impeded many applications so far.

Scientists at KIT and Queensland University of Technology (QUT) in Brisbane, Australia have now developed a new system within the 3DMM2O Cluster of Excellence.

Using special optics, the laser beam is divided into nine partial beams, which are each bundled into a focal point. All nine partial beams can be used in parallel and, thanks to improved electronic control, they can be moved rapidly and precisely. This, along with some additional technical improvements, allowed the researchers to achieve 3D printing speeds of about ten million voxels per second, which corresponds to the speed reached by graphical 2D inkjet printers.

KIT will continue to research and develop this technology. “After all, 3D printers will be used to print not just one page, but thick volumes,” says Hahn. This will require progress in chemistry, such as more sensitive photoresists are needed to generate more focal points at the same laser output.

Press release provided by KIT